How to Repair your Laguna Nose

2 posters

How to Repair your Laguna Nose

How to Repair your Laguna Nose

___________________________________________

1977 Chevelle SE x2

One Mild original

one Wild NON original

Anthony

Limey SE- Management

- Street Cred : 97

endura bumper repair

endura bumper repair

Here's how to repair that Endura bumper

For 1968, General Motors introduced a new bumper to its GTO line. Made of a hard, rubber-like material, it was to last through the dings and dents of everyday life and, if hit hard, still spring back into shape. This material, called Endura, contributed to the GTO's selection as Motor Trend's Car of the Year. By 1970, the Endura had found its way onto Firebirds and Trans Ams, and even appeared on the '71 and '72 LeMans series as the "Endura Front End" option.

During the years when the Endura was available through dealers as a replacement part, it could be ordered prepainted to match many of the popular paint codes. But today, Endura bumpers are becoming more difficult to find. An NOS bumper can fetch from $600 to $800, and good used, straight bumpers are starting to command higher prices, as well.

Endura bumper restoration has to be one of the most misunderstood subjects facing the GTO/Firebird owner. Even body shops seem to be in the dark when it comes to Pontiac's rubber snout. I've seen many cars leave the body shop with a beautiful paintjob, but a few weeks later, the nose is cracking and peeling. Here, we will take you step by step through the proper procedures to refinish one of these "rubber wonders" and make it last.

Possibly the most important step is to select a bumper worthy of restoration. If you are working with an Endura bumper that came on the car originally, check it for fit. Close inspection before removal will help the restoration later. With the fenders, hood and valance still in place, make sure there is an even gap on all sides of the bumper. By loosening the various brackets and braces, you should be able to adjust the bumper up and down or front-to-back to reach the desired position. Once happy with the fit, it can be removed by following the procedures in the shop manual for your year and car. If a bumper is being installed from another car or is a junkyard specimen, make sure it is true and straight to begin with. Lay the bumper on a flat surface, such as a concrete slab. If it rocks back and forth, there will be problems come installation time.

Since the Endura material is actually formed around a metal framework, a competent bumper shop can straighten and "tweak out" most of the alignment problems. Take a variety of measurements and cross-checks to verify where the bumper needs to be straightened. Let them know it's okay if their equipment mars or dings the Endura material, as we'll be taking care of the cosmetics later. Beginning with a straight bumper is the main concern.

Preparation

Once you have a prime candidate, it's time to start prepping the bumper for paint. Place the bumper on a suitable stand (sawhorses will do), and remove all brackets, grilles, headlights and moldings; mark or tag their location on the bumper assembly as you go. Now is a good time to clean and detail these items, so they'll be ready to reinstall later.

If your bumper has one or two minor flaws, these can be spot repaired and then repainted. If the bumper is in worse shape than most are, with chips, cracks and chunks of Endura missing, the bumper has to be stripped of all paint and primer. If you are unsure of the previous body shop's preparation "techniques," the paint should be stripped off. Better safe than sorry.

Paint removal methods

Stripping old paint and primer can be accomplished in a variety of ways. Sand, glass or plastic media blasting are by far the best. First, find as sandblasting technician who knows the difference between auto parts and granite tombstones. The nice thing about controlled media blasting is that it removes only the paint and primer from the Endura material. When the media hits bare Endura, it bounces off with no damage to the bumper.

The second method is mechanical sanding. Using either a D-A orbital sander or ajitterbug, the paint can be removed layer by layer. Starting with 80-grit sandpaper, sand all the paint off until the thin primer layer is visible. Hand sanding with 320- or 360-grit wet-or-dry paper used wet should do the job in getting to the bare Endura.

The third method is the most labor-intensive and involves hand sanding the entire bumper, starting with 180- grit wet-or-dry paper used wet. Again, stop at the primer level and finish with the 320/360-grit used wet.

You may have noticed that there was no mention of chemical strippers. These should never be used on the Endura material. Not only do they damage the surface, but the Endura will absorb the stripper like a sponge, which will cause paint problems later.

Regardless of the method you choose, use caution so that the lines and contours are not sanded away.

Repair

Now that the bumper is down to bare rubber, inspect it for cracks, chips and imperfections. Often, a bumper's painted surface may resemble the Mojave desert, but may only need sanding, priming and painting to look new again. The cracking is only in the improperly applied topcoats. Other more serious problems, such as "divots" and major chunks of material missing, require proper filling and shaping to restore the original appearance.

Any area that needs to be filled must be "roughed up" with 80-grit sandpaper. This operation provides "tooth" so the fillers have maximum adhesion to the Endura. If the bumper has severe cracks in the surface, bevel or "V' out the cracks using a Dremel tool, sandpaper or the ease of a file. Make the crack slightly wider and deeper to allow greater bonding of the filler material. If a hole or gash is evident, trim any loose material away and bevel the cut to prepare for filling.

The rubber material used in the Endura bumper is made to flex or give under pressure. To restore an Endura surface, all materials also must flex. In the past, some body shops that were not "in the know" used plastic fillers to repair these bumpers. This is the No. 1 no-no that leads to early bumper failure. Plastic fillers do not expand and contract at the same rate as Endura. Thus, in climates where there are severe temperature changes, plastic fillers don't stand a chance.

Fillers, primers and flex agents

During the heyday of the Endura bumper, GM offered a special repair kit (part No. 1050835). This kit, now long-discontinued, has been replaced by many new products that are far superior, due to advances in rubber-repair technology.

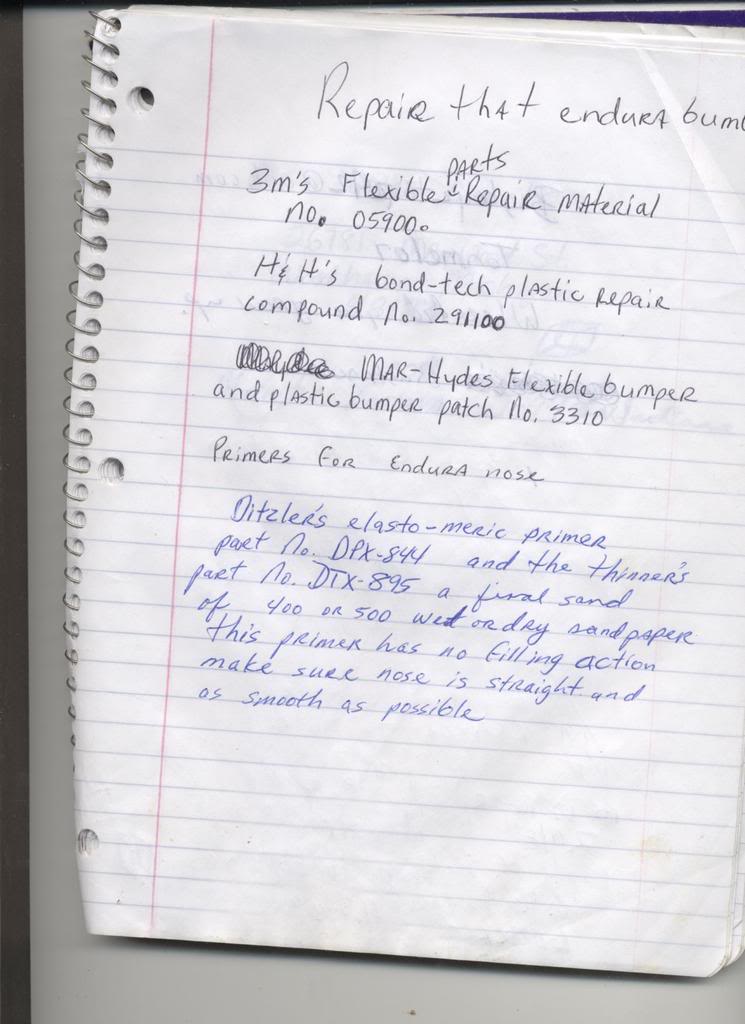

The main ingredient in Endura repair is the filler material. There are three major flexible repair materials on the market that I feel are excellent products: 3M's flexible parts repair material No. 05900, H&H's bond-tech flexible plastic repair compound No. 291100 and Mar-Hyde's flexible bumper and plastic patch No. 3310. For bonding or reattaching torn pieces, 3M's structural adhesive No. 8101 will do the trick. Always follow the manufacturer's instructions exactly.

Primers also have to be made especially for rubber bumpers. Ditzler's elasto-meric primer, part No. DPX-844, is a flexible primer that, when properly reduced, will "give" under temperature changes. A special elasto-meric lacquer thinner, part No. DTX-895, is required for reduction. When using this primer, a final sand with 400- or 500-grit wet-or-dry sandpaper used wet is recommended. This primer has little or no filling properties, so make sure the bumper is as straight and smooth as possible!

A primer I used recently with great success is Ditzler's No. K-200 with the company's flexible catalyst, part No. 248, added. Not only does it maintain a flexible consistency, it also has great filling and shaping qualities. This primer also requires a reducer that is matched to various temperatures and shop conditions.

After the bumper is primed and ready for paint, a flexative must be added to the paint to keep it pliable. Ditzler's flexative additive, part No. DX-369, can be added in with the topcoats of paint. Some of the new urethanes and basecoat/clearcoat systems may require a special flex agent.

Filler application

After "roughing up" the damaged area on the bumper, mix the two-part bumper repair material evenly according to manufacturer's instructions. I use a piece of old glass for a mixing board.

Mix the compound until it takes on a uniform color. Apply the mixture to the damaged area, making sure your first "pass" is pressed firmly into the bumper.

Apply the filler in layers until the repaired area is slightly higher than the surrounding areas. Allow there commended cure time, then block sand with 80-grit paper.

After the filler has been "cut down"to the proper contour, a final sand with 320- or 360-grit wet-or-dry used wet should smooth out everything. If small imperfections or pin holes are found in the repaired surface, a light coat of repair material over the area should do the trick.

Always remember to make sure the bumper is completely dry before applying any fillers, especially after water sanding.

Priming and painting

After close inspection of the repaired areas for defects, the bumper can be primed. If the primer selected is the No. K-200 (my choice), mix enough of the primer catalyst and reducer to do the job. Once mixed, the primer has a limited time frame in which it can be applied. Apply enough primer to cover the bumper and all repaired areas. Avoid excessive coats, and allow plenty of "flash" time between coats. After the primer has cured, it can be sanded with 400- or 500-grit wet-or-dry with plenty of water.

To help during your sanding operation, a "guide coat" of a contrasting color can be sprayed over the bumper's surface (spray cans work well). This guide coat will help you detect scratches and defects that otherwise would go unnoticed.

If, during the sanding operation, you sanded into the rubber Endura or into a repaired area, these spots must be covered again with primer before painting. No bare rubber or repair material should be showing.

At this stage, your project should be properly prepared. It should be free of scratches and defects, and should have a nice smooth primered and sanded surface.

Now is the time to see all that work come to life. You also have to make a decision as to whether to reinstall the bumper or paint it while it is off the car. Although both methods have their good and bad points, I prefer to paint it off the car. When the remainder of the car is ready to paint, position the bumper on a suitable stand or covered sawhorse. The bumper should be close to the car durign painting, but not close enough to draw overspray from painting of the car body.

As mentioned throughout this article, all materials must be flexible, and paint topcoats are no exception. There are different flexatives on the market that are designated for different types of paint. Lacquers and acrylic enamels may take one flex agent, urethanes and epoxy-based paints another. Pick the right one for your application.

The easiest way to paint a car equipped with an Endura bumper is with the two-spray-gun method. One is used for the Endura bumper with the flex agent added to the paint, while the other is used to paint the remainder of the car.

If this seems a little complicated, consider the alternative: You can install and adjust the bumper on the car, mask the bumper completely to protect it from overspray, paint the complete car and allow it to dry. Then mask off the rest of the car to protect it from overspray while the bumper is being painted. The choice is yours. Whichever method you choose, make sure the same number of coats are used on the bumper as on the rest of the body.

After painting and curing the Endura bumper, it can be polished to a high luster if necessary. Hand rubouts are recommended. Save the electric polishers for the experts!

Maintenance is simple from here on. Keep the surface clean and waxed, along with the rest of the car, and you should have an enduring Endura bumper that will look good for years to come.

For 1968, General Motors introduced a new bumper to its GTO line. Made of a hard, rubber-like material, it was to last through the dings and dents of everyday life and, if hit hard, still spring back into shape. This material, called Endura, contributed to the GTO's selection as Motor Trend's Car of the Year. By 1970, the Endura had found its way onto Firebirds and Trans Ams, and even appeared on the '71 and '72 LeMans series as the "Endura Front End" option.

During the years when the Endura was available through dealers as a replacement part, it could be ordered prepainted to match many of the popular paint codes. But today, Endura bumpers are becoming more difficult to find. An NOS bumper can fetch from $600 to $800, and good used, straight bumpers are starting to command higher prices, as well.

Endura bumper restoration has to be one of the most misunderstood subjects facing the GTO/Firebird owner. Even body shops seem to be in the dark when it comes to Pontiac's rubber snout. I've seen many cars leave the body shop with a beautiful paintjob, but a few weeks later, the nose is cracking and peeling. Here, we will take you step by step through the proper procedures to refinish one of these "rubber wonders" and make it last.

Possibly the most important step is to select a bumper worthy of restoration. If you are working with an Endura bumper that came on the car originally, check it for fit. Close inspection before removal will help the restoration later. With the fenders, hood and valance still in place, make sure there is an even gap on all sides of the bumper. By loosening the various brackets and braces, you should be able to adjust the bumper up and down or front-to-back to reach the desired position. Once happy with the fit, it can be removed by following the procedures in the shop manual for your year and car. If a bumper is being installed from another car or is a junkyard specimen, make sure it is true and straight to begin with. Lay the bumper on a flat surface, such as a concrete slab. If it rocks back and forth, there will be problems come installation time.

Since the Endura material is actually formed around a metal framework, a competent bumper shop can straighten and "tweak out" most of the alignment problems. Take a variety of measurements and cross-checks to verify where the bumper needs to be straightened. Let them know it's okay if their equipment mars or dings the Endura material, as we'll be taking care of the cosmetics later. Beginning with a straight bumper is the main concern.

Preparation

Once you have a prime candidate, it's time to start prepping the bumper for paint. Place the bumper on a suitable stand (sawhorses will do), and remove all brackets, grilles, headlights and moldings; mark or tag their location on the bumper assembly as you go. Now is a good time to clean and detail these items, so they'll be ready to reinstall later.

If your bumper has one or two minor flaws, these can be spot repaired and then repainted. If the bumper is in worse shape than most are, with chips, cracks and chunks of Endura missing, the bumper has to be stripped of all paint and primer. If you are unsure of the previous body shop's preparation "techniques," the paint should be stripped off. Better safe than sorry.

Paint removal methods

Stripping old paint and primer can be accomplished in a variety of ways. Sand, glass or plastic media blasting are by far the best. First, find as sandblasting technician who knows the difference between auto parts and granite tombstones. The nice thing about controlled media blasting is that it removes only the paint and primer from the Endura material. When the media hits bare Endura, it bounces off with no damage to the bumper.

The second method is mechanical sanding. Using either a D-A orbital sander or ajitterbug, the paint can be removed layer by layer. Starting with 80-grit sandpaper, sand all the paint off until the thin primer layer is visible. Hand sanding with 320- or 360-grit wet-or-dry paper used wet should do the job in getting to the bare Endura.

The third method is the most labor-intensive and involves hand sanding the entire bumper, starting with 180- grit wet-or-dry paper used wet. Again, stop at the primer level and finish with the 320/360-grit used wet.

You may have noticed that there was no mention of chemical strippers. These should never be used on the Endura material. Not only do they damage the surface, but the Endura will absorb the stripper like a sponge, which will cause paint problems later.

Regardless of the method you choose, use caution so that the lines and contours are not sanded away.

Repair

Now that the bumper is down to bare rubber, inspect it for cracks, chips and imperfections. Often, a bumper's painted surface may resemble the Mojave desert, but may only need sanding, priming and painting to look new again. The cracking is only in the improperly applied topcoats. Other more serious problems, such as "divots" and major chunks of material missing, require proper filling and shaping to restore the original appearance.

Any area that needs to be filled must be "roughed up" with 80-grit sandpaper. This operation provides "tooth" so the fillers have maximum adhesion to the Endura. If the bumper has severe cracks in the surface, bevel or "V' out the cracks using a Dremel tool, sandpaper or the ease of a file. Make the crack slightly wider and deeper to allow greater bonding of the filler material. If a hole or gash is evident, trim any loose material away and bevel the cut to prepare for filling.

The rubber material used in the Endura bumper is made to flex or give under pressure. To restore an Endura surface, all materials also must flex. In the past, some body shops that were not "in the know" used plastic fillers to repair these bumpers. This is the No. 1 no-no that leads to early bumper failure. Plastic fillers do not expand and contract at the same rate as Endura. Thus, in climates where there are severe temperature changes, plastic fillers don't stand a chance.

Fillers, primers and flex agents

During the heyday of the Endura bumper, GM offered a special repair kit (part No. 1050835). This kit, now long-discontinued, has been replaced by many new products that are far superior, due to advances in rubber-repair technology.

The main ingredient in Endura repair is the filler material. There are three major flexible repair materials on the market that I feel are excellent products: 3M's flexible parts repair material No. 05900, H&H's bond-tech flexible plastic repair compound No. 291100 and Mar-Hyde's flexible bumper and plastic patch No. 3310. For bonding or reattaching torn pieces, 3M's structural adhesive No. 8101 will do the trick. Always follow the manufacturer's instructions exactly.

Primers also have to be made especially for rubber bumpers. Ditzler's elasto-meric primer, part No. DPX-844, is a flexible primer that, when properly reduced, will "give" under temperature changes. A special elasto-meric lacquer thinner, part No. DTX-895, is required for reduction. When using this primer, a final sand with 400- or 500-grit wet-or-dry sandpaper used wet is recommended. This primer has little or no filling properties, so make sure the bumper is as straight and smooth as possible!

A primer I used recently with great success is Ditzler's No. K-200 with the company's flexible catalyst, part No. 248, added. Not only does it maintain a flexible consistency, it also has great filling and shaping qualities. This primer also requires a reducer that is matched to various temperatures and shop conditions.

After the bumper is primed and ready for paint, a flexative must be added to the paint to keep it pliable. Ditzler's flexative additive, part No. DX-369, can be added in with the topcoats of paint. Some of the new urethanes and basecoat/clearcoat systems may require a special flex agent.

Filler application

After "roughing up" the damaged area on the bumper, mix the two-part bumper repair material evenly according to manufacturer's instructions. I use a piece of old glass for a mixing board.

Mix the compound until it takes on a uniform color. Apply the mixture to the damaged area, making sure your first "pass" is pressed firmly into the bumper.

Apply the filler in layers until the repaired area is slightly higher than the surrounding areas. Allow there commended cure time, then block sand with 80-grit paper.

After the filler has been "cut down"to the proper contour, a final sand with 320- or 360-grit wet-or-dry used wet should smooth out everything. If small imperfections or pin holes are found in the repaired surface, a light coat of repair material over the area should do the trick.

Always remember to make sure the bumper is completely dry before applying any fillers, especially after water sanding.

Priming and painting

After close inspection of the repaired areas for defects, the bumper can be primed. If the primer selected is the No. K-200 (my choice), mix enough of the primer catalyst and reducer to do the job. Once mixed, the primer has a limited time frame in which it can be applied. Apply enough primer to cover the bumper and all repaired areas. Avoid excessive coats, and allow plenty of "flash" time between coats. After the primer has cured, it can be sanded with 400- or 500-grit wet-or-dry with plenty of water.

To help during your sanding operation, a "guide coat" of a contrasting color can be sprayed over the bumper's surface (spray cans work well). This guide coat will help you detect scratches and defects that otherwise would go unnoticed.

If, during the sanding operation, you sanded into the rubber Endura or into a repaired area, these spots must be covered again with primer before painting. No bare rubber or repair material should be showing.

At this stage, your project should be properly prepared. It should be free of scratches and defects, and should have a nice smooth primered and sanded surface.

Now is the time to see all that work come to life. You also have to make a decision as to whether to reinstall the bumper or paint it while it is off the car. Although both methods have their good and bad points, I prefer to paint it off the car. When the remainder of the car is ready to paint, position the bumper on a suitable stand or covered sawhorse. The bumper should be close to the car durign painting, but not close enough to draw overspray from painting of the car body.

As mentioned throughout this article, all materials must be flexible, and paint topcoats are no exception. There are different flexatives on the market that are designated for different types of paint. Lacquers and acrylic enamels may take one flex agent, urethanes and epoxy-based paints another. Pick the right one for your application.

The easiest way to paint a car equipped with an Endura bumper is with the two-spray-gun method. One is used for the Endura bumper with the flex agent added to the paint, while the other is used to paint the remainder of the car.

If this seems a little complicated, consider the alternative: You can install and adjust the bumper on the car, mask the bumper completely to protect it from overspray, paint the complete car and allow it to dry. Then mask off the rest of the car to protect it from overspray while the bumper is being painted. The choice is yours. Whichever method you choose, make sure the same number of coats are used on the bumper as on the rest of the body.

After painting and curing the Endura bumper, it can be polished to a high luster if necessary. Hand rubouts are recommended. Save the electric polishers for the experts!

Maintenance is simple from here on. Keep the surface clean and waxed, along with the rest of the car, and you should have an enduring Endura bumper that will look good for years to come.

muldokken- G3GM Newbie

- Street Cred : 0

Permissions in this forum:

You cannot reply to topics in this forum|

|

|

» 1973 Chevelle SS, 350, 4spd. build

» Who works on 73-77 "soft" steering wheels?

» Blue door jamb sticker

» Factory am/fm

» Painting Interior Plastic

» Need driver side bucket seat 73 Laguna

» triangle stainless window trim

» door interior trim retainer clips

» Rusty's progress motor Parts arrived LOL Half are on